What are the printing processes for bogg tote bags?

There are mainly the following printing methods for EVA beach bags:

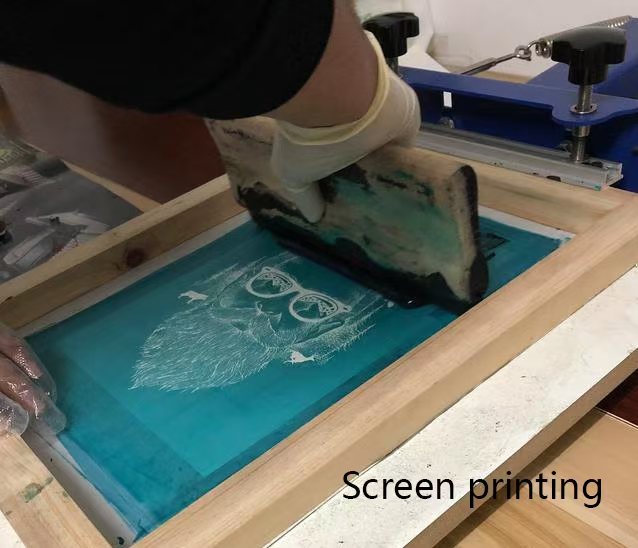

Screen printing

• First, make a screen plate according to the design pattern, and the pattern part on the plate is hollowed out. Then pour the color-adjusted printing paste on the screen, and use a scraper to print the paste through the hollow part to the surface of the EVA beach bag.

• The advantages are bright colors, strong three-dimensional sense and covering power, and can print a variety of colors and complex patterns at a low cost; the disadvantages are that it cannot print very fine patterns, the printing speed is slow, and it is not suitable for large-scale production.

Water transfer

• First print the designed pattern on special water transfer paper, then put the paper into water, separate the pattern from the paper and float on the water surface, then slowly put the EVA beach bag into the water, so that the pattern is evenly transferred to the surface of the bag, and finally dry it to fix the pattern.

• The advantage is that high-precision and colorful patterns can be printed on complex shapes and curved surfaces, and the patterns have strong adhesion and are not easy to fade; the disadvantages are complex processes, high costs, and certain requirements for environmental humidity and temperature.

Thermal transfer

• Transfer the pattern on the transfer paper or film to the EVA beach bag through high temperature and high pressure. First print the pattern on the transfer paper, then stick the EVA beach bag to the transfer paper and put it into the heat transfer machine. Under high temperature and high pressure, the pattern ink on the transfer paper sublimates and penetrates into the EVA material to form a firm print.

• The advantages are clear patterns, bright colors, high firmness, and photo-level printing effects; the disadvantages are high equipment and consumables costs, and high technical requirements for operators.

High-frequency embossing

• Using a high-frequency machine and a copper mold, place the EVA beach bag on the workbench of the high-frequency machine, and place the copper mold on the surface of the bag where the pattern needs to be embossed. Start the machine, and the high-frequency electromagnetic field causes the molecules inside the material to collide violently with each other to generate high temperature, and the pattern on the copper mold is embossed onto the EVA beach bag.

• The advantages are that the embossed pattern is three-dimensional, full, durable, not easy to fall off or wear, and can be customized in various shapes, sizes and colors; the disadvantages are large equipment investment, high mold production costs, and it is not suitable for small batch and multi-variety production.